Modular Design and Construction with BIM

Building Information Modeling (BIM) has revolutionized the way the construction industry designs and constructs buildings. It has become an indispensable tool for architects, engineers, and construction professionals to visualize and construct complex structures. BIM not only facilitates a more collaborative and coordinated design process, but it also helps to optimize building performance, reduce project costs, and improve project delivery times.

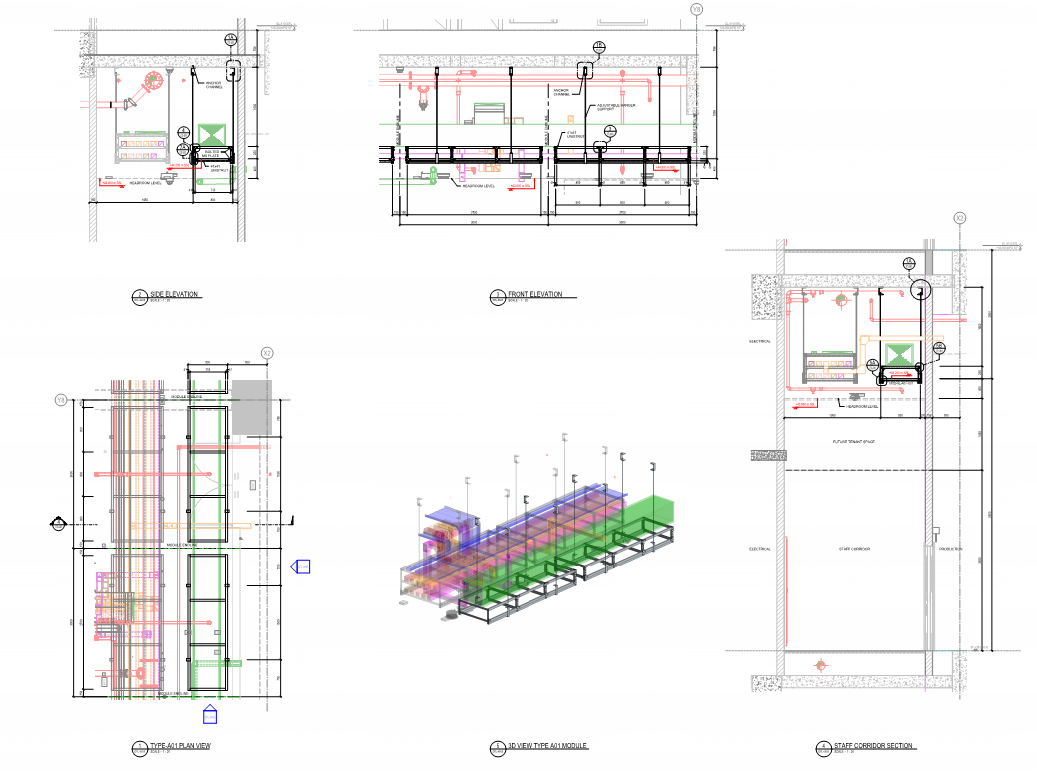

One of the many benefits of BIM is the ability to produce MEP (Mechanical, Electrical, and Plumbing) modules. MEP modules are prefabricated components that contain MEP systems such as ductwork, piping, and electrical trunking or trays. These modules are designed to fit together seamlessly and can be installed quickly and efficiently on site.

Increased Efficiency: The use of BIM technology allows MEP systems to be designed and visualized in 3D, providing greater clarity and precision. The ability to see a virtual representation of the system before it is constructed enables designers to identify and resolve any potential conflicts or clashes before installation. This results in fewer changes and rework on site, saving time and money.

Improved Collaboration: BIM facilitates collaboration between different disciplines in the construction process, including architects, engineers, and contractors. By using a shared model, the project team can work together to develop MEP modules. This collaboration can lead to improved design, fewer clashes, and a more coordinated project.

Reduced Waste: By producing MEP modules offsite, in a controlled environment, waste is reduced. This is because the modules are manufactured to precise specifications, with minimal material waste. Additionally, the reduced construction waste on site contributes to a more sustainable construction process.

Improved Quality: The use of BIM for MEP module production leads to increased quality control. The precision of the modeling ensures that the modules are manufactured accurately, reducing the potential for errors and defects. Additionally, the offsite production of the modules ensures that the work is carried out in a controlled environment, further improving quality.

Faster Installation: The use of MEP modules will reduce installation time on site. The prefabricated modules are delivered and installed quickly, expediating the overall project timeline. Additionally, the modules can be installed with minimal disruption to other works, further contributing to faster project delivery times.

Examples of Prefabricated Modules

Prefabricated Bathroom Pods

Bathroom pods are fully finished, prefabricated units that include all necessary MEP systems, fixtures, and finishes. They can be customized to fit specific project requirements and can be installed in a matter of hours. Bathroom pods are often used in hotels, hospitals, airports, and other commercial buildings to speed up construction and reduce costs.

Prefabricated Mechanical Rooms

Mechanical Rooms are designed to for HVAC (heating, ventilation, and air conditioning) equipment, piping, and electrical components. These rooms are prefabricated offsite and can be installed quickly on site. They are often used in multi-unit residential buildings, office buildings, and where repeatable plant room and equipment can be deployed.

Electrical Distribution Centers

Electrical distribution centers (EDCs) are prefabricated units that house electrical panels, transformers, and other electrical components. These units are designed to be installed in a variety of settings, including commercial buildings, data centers, and industrial facilities. EDCs can be customized to meet specific project requirements.

Modular Chilled Water Plants

Modular chilled water plants are prefabricated units that include all necessary components for a chilled water system, including pumps, chillers, and cooling towers. These plants are often used in large commercial buildings and industrial facilities to provide air conditioning and cooling.

Fire Protection Systems

Prefabricated fire protection systems are designed to include all necessary components for a complete fire protection system, including sprinklers, pumps, and piping. They are often used in commercial and industrial buildings to meet fire safety codes and regulations.

What are the BIM Deliverables of a Modular Project?

3D BIM Models are used to generate detailed 3D models of the MEP modules. These models can include all of the components of the modules, such as ductwork, piping, and electrical conduit, and can be used to optimize the design and ensure that the modules will fit together seamlessly.

Clash Detection is a process that identifies conflicts between different building systems. By using the BIM model, MEP designers can identify potential clashes between the MEP modules and other building systems, such as structural components or architectural features. This can help to reduce errors and improve project coordination. The modules must undergo a thorough clash analysis to avoid any conflicts on site during installation to ensure seamless integration.

Shop Drawings are detailed drawings that show the fabrication and installation of the MEP modules. Using the BIM model, MEP designers and contractors can create accurate shop drawings that include all necessary information, such as dimensions, materials, and installation requirements. The BIM Execution Plan should clearly state the process and requirements of shop drawing production for modules from the models.

Material Lists can be generated for the MEP modules. These lists can include all necessary materials, such as piping, ductwork, and electrical components, and can be used to optimize the supply chain to reduce waste and cost.

Installation Drawings show the sequence and methods of to install the MEP modules. By using the BIM model, MEP designers can create accurate drawings that include the the location of the modules and their required sequence of installation. These can be further illustrated by creating a 4D construction method statement to further elaborate the entire process, including temporary storage facilities and safety concerns when working with modules.

Tips to Implement an Effective Modular Design and Construction Process.

Set Clear Expectations for the use of MEP modules early in the project. Ensure all stakeholders, including the design team, contractors, and subcontractors, understand that MEP modules will be a requirement of the project.

Hire Experienced MEP Designers who have a track record of incorporating modular design into their projects. They can help to design modules that are optimized for efficiency, quality, and cost-effectiveness before a contractor is involved in the project. Frequently, modular design solutions are an afterthought on a project by the main contractor to improve their tender and construction process, but can often leave shortcomings in the overall design compared to being designed from the onset of the project.

Collaborate with Contractors early in the design process and involve them in the development of the modular designs. Contractors can provide valuable input on the feasibility of modular construction and can help to optimize the design for efficient installation.

Specify Modular Design in Tender Documents for MEP modules in the project tender documents. This will help to ensure that contractors and subcontractors understand the requirements and are able to bid the work more accurately.

Monitor the Module Coordination Process and attend the BIM coordination meetings for modular design and installation activities. This will help ensure the process is being followed and results will satisfy the project requirements. MEP modules are critical facilities that will have impacts on the architecture, structure, operations, and maintenance of the project.

Monitor the Construction Process: During the construction process, monitor the implementation of MEP modules to ensure that they are being installed correctly and efficiently. Conduct regular site visits and quality control checks to ensure that the modules are meeting project specifications and quality standards.

Review the Modular Project by examining the modular activities from design to installation from different stakeholders perspectives and the impacts they had on the design, coordination, cost, fabrication, installation, and operation will be very helpful to make improvements to the design and process for future modular projects.

In conclusion, the production of MEP modules with BIM offers numerous benefits. The increased efficiency, improved collaboration, reduced waste, improved quality, and faster installation times contribute to a more cost-effective and sustainable construction process. As the construction industry continues to adopt BIM, the use of MEP modules is likely to become more widespread, leading to more efficient and effective construction projects.

Modular Construction Terminology

MMC - Modern Methods of Construction

DfMA - Design for Manufacture and Assembly

PBC - Prefabricated Building Components

OSM - Offsite Manufacturing

MiMEP - Modular Integrated MEP

BIM - Building Information Modeling

SIPs - Structural Insulated Panels

MiC - Modular Integrated Construction

We hope you enjoyed reading.

If you are looking for modular solutions with BIM, contact us today to discover how we can help you.